Our design office

For our design office, every part we make is a work of art, made to measure to suit the specific needs of the agricultural sector. We work steel with expertise and passion to meet the challenges raised by your projects. Each fold, curve and detail is designed to precision, combining tradition with innovation to provide you with sustainable high-performance solutions. Let us help you with your projects and let’s cultivate excellence together.

Our Design Office’s approach

Needs analysis:

We start by a comprehensive analysis of the client’s specific needs. Understanding the technical and functional requirements of agricultural equipment and machinery allows us to understand the challenges that will have to be faced.

Personalised, creative design :

Using the results of this analysis, our designers will come up with bespoke solutions combining creativity with technical expertise. Each part is designed for optimal performance and wear, whilst also meeting environmental operating constraints.

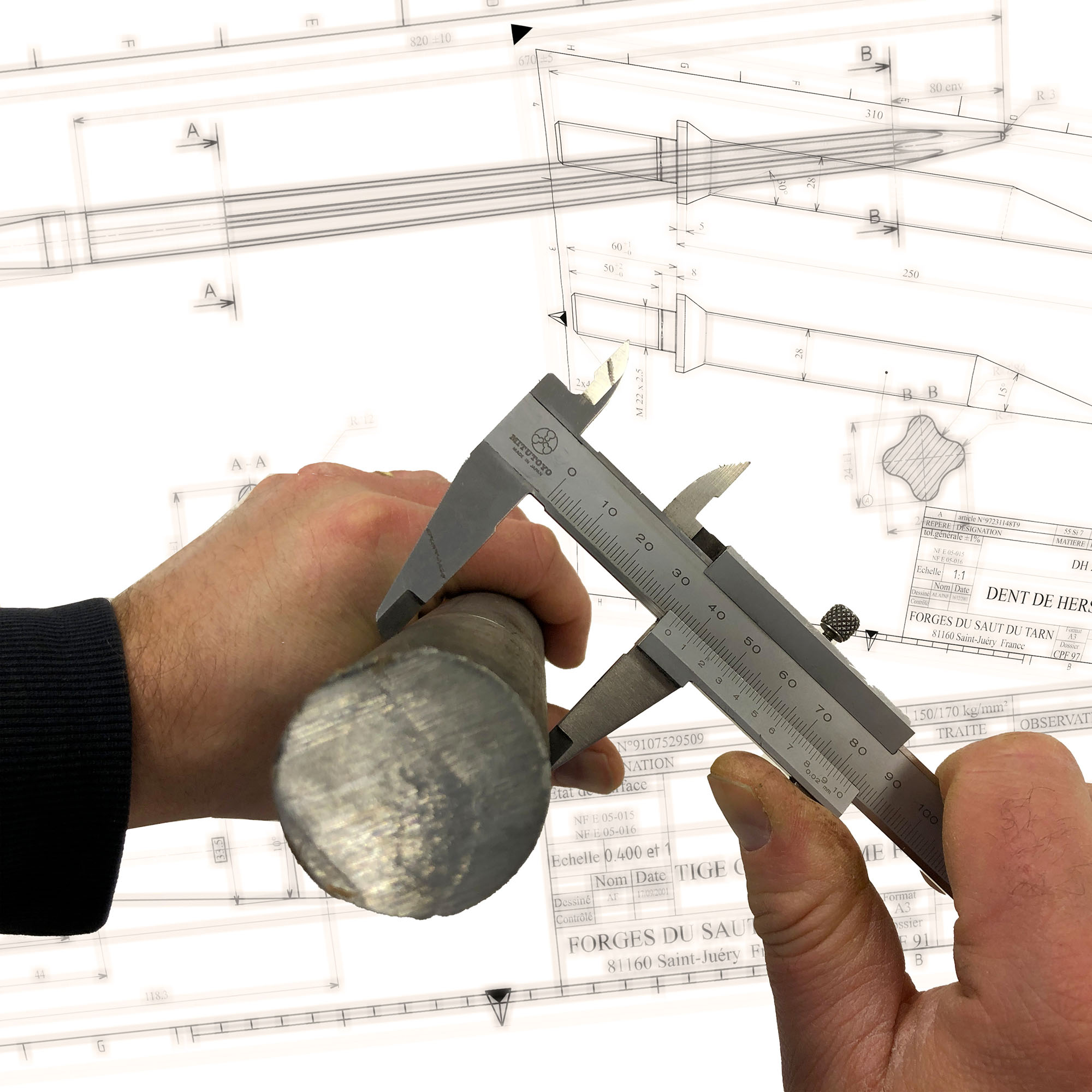

Prototyping and validation:

We always make prototypes before starting mass production. These one-off parts allow us to test out their viability and performance under real operating conditions. The feedback from this is used to complete the design work.

Prototyping and validation:

We always make prototypes before starting mass production. These one-off parts allow us to test out their viability and performance under real operating conditions. The feedback from this is used to complete the design work.

Quality manufacture and rigorous inspections:

Once the prototype has been validated, we launch the manufacture process following the highest quality control standards. Each production stage is monitored closely, from the selection of raw materials right up to the final inspections, thus guaranteeing that the manufactured parts are reliable and effective; ready to face the rigours of the agricultural world.

Quality manufacture and rigorous inspections:

Once the prototype has been validated, we launch the manufacture process following the highest quality control standards. Each production stage is monitored closely, from the selection of raw materials right up to the final inspections, thus guaranteeing that the manufactured parts are reliable and effective; ready to face the rigours of the agricultural world.

Our commitments

Innovation and development

We are committed to developing innovative products combining tradition with technology to meet the specific needs of our clients. We design bespoke solutions with passion and rigour, guaranteeing their function, resistance and aesthetics.

Adaptation to forge processes

We are committed to ensuring the management of each stage of the forging process, from the selection of the raw materials to the finishing of the parts. We guarantee the highest quality standards with expertise and attention to detail in order to manufacture reliable high-performance products.

Heat treatment expertise

Our design office attributes the highest importance to the management of the heat treatment processes. Our expertise and cutting edge technology ensure that heat treatments are precise and rigorous, resulting in forged parts with optimal mechanical properties.

Integrity and transparency

Would you like to speak with our design office?

Don’t hesitate to call our departments to talk about your project.

Our staff are available to listen to your needs and present solutions that will meet your expectations.